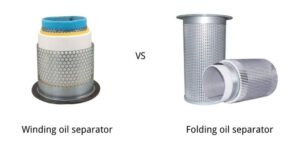

Air compressor filter elements play a crucial role in keeping equipment running smoothly. Among them, oil separators are essential for removing oil mist and impurities from compressed air. Winding and folding type oil separators are both widely used, it can be confusing to know which one is right for your application.

In this article, we compare winding Oil Separators and folding Oil Separators, highlighting their working principles, advantages, and best use cases.

How Oil Separators Work

Oil separators are designed to filter out oil mist and solid particles from compressed air. As compressed air passes through the fiber filter media, fine oil droplets (often less than 1 micron) collide, diffuse, and coalesce into larger droplets. These larger droplets then collect at the bottom of the filter element and return to the lubrication system.

The size of the filtering surface directly affects dirt-holding capacity, pressure drop, and the service life of the separator element.

Winding Oil Separators: Features & Applications

Deep filtration: Multiple tightly wound layers of fiberglass filter media provide fine separation.

Lower oil carryover: Precision is generally higher compared to folding types.

Higher pressure resistance: The wound structure can withstand greater operating pressures.

Common use: Standard and high-pressure compressors.

👉 Best suited for: Most general air compressor applications, especially where oil content sensitivity or high pressure is required.

Folding Oil Separators: Features & Applications

Large filtering area: Folding oil separators offer at least 3× the filtering surface compared to winding designs of the same size.

Longer service life: Larger surface area means higher dirt-holding capacity and lower pressure drop.

Flexible design: Surface area can be increased through pleating, allowing more airflow and better separation efficiency.

High requirements: Manufacturing demands higher precision in technology and equipment.

👉 Best suited for: Long-life applications, high load conditions, and low-pressure compressors.

Which Oil Separator Should You Choose?

If you need longer life, high efficiency, and low pressure drop → choose a folding oil separator.

If your compressor operates at higher pressure or under standard conditions → a winding oil separator is more reliable.

For special cases like variable frequency compressors, a composite design (folding + winding) may be the best solution.

Conclusion

Both winding Oil Separators and folding Oil Separators have unique strengths. The right choice depends on your compressor type, working conditions, and oil content requirements. By selecting the correct oil separator, you can reduce operating costs, extend equipment life, and improve compressed air quality.

FiltraMate provides high-quality replacement oil separators designed for various compressor brands and models. Contact us today to find the best solution for your needs.