Stainless steel Five-layer sintered mesh

Product Introduction

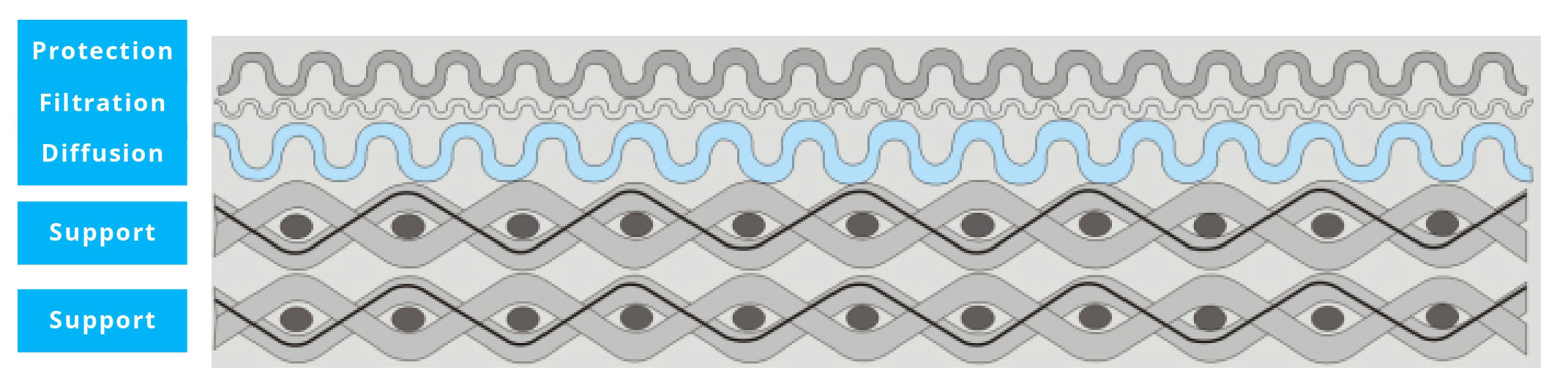

The standard five-layer sintered mesh is a high-performance filtration material made from multiple layers of stainless steel woven mesh, including a protective layer, precision filtration layer, dispersion layer, and support layer.

After vacuum sintering and press forming, it provides uniform pore distribution, stable filtration accuracy, and exceptional mechanical strength.

With its smooth pore channels and surface filtration structure, this material offers excellent backwashing and regeneration performance, making it ideal for long-term, repeated use.

It is widely used to manufacture sintered mesh filter elements in demanding industries that require high pressure resistance, stable precision, and continuous automated operation.

The mesh is easy to cut, bend, weld, and form into various shapes such as discs, cylinders, cones, corrugated filters, and custom components.

Structure drawing

[caption id="attachment_2011" align="alignnone" width="580"]

five-layer sintered mesh structrual drawing[/caption]

Product Features

High Strength & Rigidity

• Outstanding mechanical and compression strength

• Easy to weld, fabricate, and assembleUniform & Stable Filtration Precision

• Consistent pore size across the entire structure

• No deformation or precision loss during useWide Operating Temperature Range

• Suitable for -200°C to 600°C

• Excellent resistance to acids, alkalis, and corrosive mediaExcellent Cleanability & Long Service Life

• Supports backwashing, reverse flow, ultrasonic cleaning, baking, melting, etc.

• Reusable over long periods with stable performance

Technical Specifications

Material Options

• Standard: SUS304, SUS316L

• Optional: Monel alloy, 904L, C276, 2205, 2507, and more

Available Sizes

• 1000 × 500 mm

• 1000 × 600 mm

• 1000 × 1000 mm

• 1200 × 1000 mm

• 1200 × 1200 mm

(Custom dimensions available upon request)

Filtration Precision

• 1–300 μm

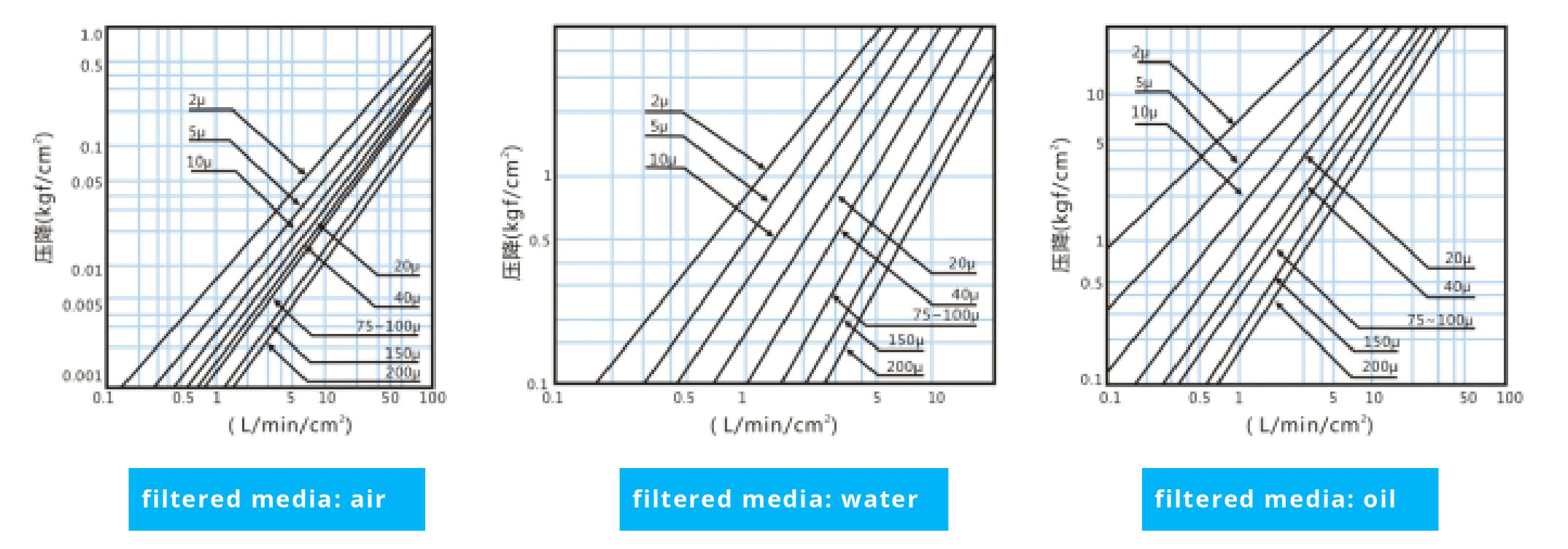

Pressure drop features

FAQs

1. What is a five-layer sintered mesh used for?

It is used for precise filtration in high-pressure, high-temperature, or corrosive environments. Common applications include chemical processing, filtration equipment, polymer filtration, oil & gas, and sintered mesh filter element production.

2. Can the sintered mesh be cleaned and reused?

Yes. It supports backwashing, ultrasonic cleaning, reverse flow, baking, or chemical cleaning. Its structure is strong and stable, allowing long-term repeated use.

3. What filtration precision options are available?

The standard filtration range is 1–300 μm, and customized precision levels are available for specific applications.

4. Can this material be customized in size or material?

Absolutely. Besides standard 304 and 316L stainless steel, materials like Monel, 904L, C276, 2205, and 2507 can be manufactured in custom sizes and shapes.