PP Melt Blown Filter Cartridge

Product Overview

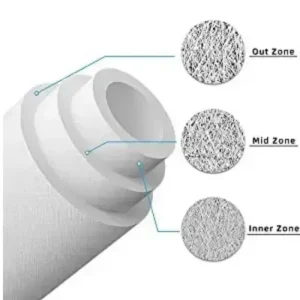

The PP melt blown filter cartridge is a depth filter. It originates from polypropylene(PP) pellets, which are melted and extruded through precise nozzles. The polypropylene (PP) fibers are melt-blown around a core without chemical adhesives. The randomly distributed fibers form a three-dimensional micro-porous structure, enabling surface, depth, and coarse filtration simultaneously.

With its gradually densified pore structure, this filter delivers large dirt-holding capacity, high filtration accuracy, and low differential pressure. It efficiently removes suspended matter, particulates, rust, and other impurities, ensuring reliable performance and long service life.

Key Features

Gradient Density Structure: Optimized dirt-holding capacity with gradual pore size reduction.

Strengthened Fiber Surface: Prevents fiber shedding during operation.

High Filtration Accuracy: Superfine PP fibers for precise filtration.

Corrosion Resistance: Made from 100% pure polypropylene.

Expanded Filtration Area: Groove or grain surface design increases effective filtration area.

Technical Specifications

Dimensions:

Outer Diameter: 63 mm, 115 mm

Inner Diameter: 28 mm, 30 mm

Lengths: 10″, 20″, 30″, 40″

Material Composition:

Media: Polypropylene (PP)

Core: Polypropylene (PP)

End Caps: Polypropylene (PP)

Gaskets/Seals: Silicone rubber, EPDM, NBR, Fluoro rubber

Filtration Accuracy: 1 μm, 5 μm, 10 μm, 20 μm, 30 μm, 50 μm, 75 μm, 100 μm

Max Operating Temperature: 65°C

Max Differential Pressure: 2.0 bar @ 21°C

Surface finishes: flat, needled, grooved

Applications

The PP melt blown filter is widely used for liquid filtration across industries:

Drinking water and RO reverse osmosis systems

Acid and alkali fluids in chemical processing

Industrial water treatment and electroplating solutions

Ink, coating, and display solutions

Pre-filtration for sterile water and ultrapure water

Chemical raw materials and organic solvent filtration

For more water filter cartridges, please check our water portforlio.