Nickel Fiber Felt

Product Overview

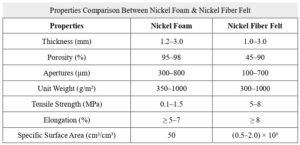

Nickel Fiber Felt is a porous metallic material engineered from micron-scale nickel fibers through advanced sintering technology. Its three-dimensional reticulated structure, high porosity (45–90%), and excellent conductivity make it an ideal electrode and gas diffusion layer (GDL) material in hydrogen production by water electrolysis.

In Anion exchange membrane (AEM) electrolyzers and alkaline electrolyzers (ALK) , nickel fiber felt ensures efficient gas evolution, rapid electrolyte penetration, and stable current distribution, directly improving hydrogen generation efficiency and system stability. Compared to traditional nickel mesh or powder sintered plates, nickel fiber felt offers lower polarization resistance, longer lifespan, and superior corrosion resistance, making it a preferred choice for the clean hydrogen energy industry.

Key Features

• Optimized for Water Electrolysis – Ensures efficient hydrogen and oxygen evolution with uniform gas diffusion.

• High Electrical & Thermal Conductivity – Supports stable current flow, reducing energy losses.

• High Porosity & Surface Area – Facilitates rapid electrolyte transport and enhanced reaction kinetics.

• Excellent Corrosion Resistance – Stable in alkaline and acidic electrolyzer environments.

• Durable & Long-Life – Resistant to high pressure, temperature, and repeated operational cycles.

• Customizable – Available in sheets, discs, or custom electrode designs to meet electrolyzer specifications.

Specifications

• Material Options: Pure Nickel (Ni200, Ni201, N6)

• Purity: ≥ 99%

• Fiber Diameter: 6–40 μm

• Porosity: 45–90%

• Thickness: 0.1–1.5 mm (customizable)

• Permeability: > 350L/mindm²

• Operating Temperature: Up to 1000°C

• Size Options: 100×100 mm, 200×200 mm, 500×500 mm, 600×1000 mm, or customized for electrolyzer stacks

Applications

Nickel fiber felt is widely applied in hydrogen energy systems and beyond:

• Hydrogen Production

Anion Exchange Membrane (AEM) electrolyzers

Alkaline water electrolyzers (ALK)

Anode/cathode diffusion layers for efficient gas release

Redox flow batteries & hydrogen fuel cell stacks

• Electrochemical & Energy Storage

Catalyst support for hydrogen and oxygen evolution reactions (HER/OER)

Supercapacitors and advanced batteries

• Industrial & Aerospace

High-temperature filtration of gases and liquids

Corrosion-resistant structural components in aerospace fuel systems

• Environmental & Chemical Processing

Electrochemical wastewater treatment

Gas purification and catalytic reactions

Depending on the working conditions, sometimes manufacturers also use stainless steel sintered fiber felt in hydrogen production by water electrolysis.