Stainless Steel Sintered Metal Fiber Felt

Product Introduction:

Stainless steel sintered metal fiber felt is produced by sintering extremely fine stainless steel fibers (micron-level diameter) after non-woven layering and high-temperature treatment. The final felt has a gradient pore structure across different layers, enabling high filtration accuracy and large contaminant holding capacity. With its 3D porous network, high porosity, large surface area, and uniform pore size distribution, it ensures consistent surface filtration performance. Thanks to these properties, sintered felt overcomes the clogging and fragility issues of traditional mesh and powder filters. It offers superior temperature and pressure resistance, making it an ideal choice for high-temperature, corrosion-resistant, and high-precision filtration applications.

Product Features:

Sintered metal fiber felt is a three-dimensional structure, that could hold higher dirt than sintered wire mesh. Stainless steel sintered fiber felt exhibit excellent filtration performance, making them ideal high-temperature-resistant, corrosion-resistant, and high-precision filtration materials. They are widely used in polymer filtration, petrochemicals, high-temperature gas purification in electronics, oil refining process filtration, viscous liquid filtration, pre-filtration for ultrafiltration systems, vacuum pump protection filters, membrane supports, catalyst carriers, automotive airbags, fuel filtration for aircraft and ships, and hydraulic system filtration.

Technical Specifications:

Standard sizes:

1000mm × 500mm

1000mm × 600mm

1000mm × 1000mm

1200mm × 1000mm

Maximum size: 1480mm × 1000mm

Standard material: SUS316L

Custom dimensions available upon request.

Advantages:

1. High dirt-holding capacity, high filtration accuracy, slow pressure rise, and long replacement cycles;

2. High porosity and excellent permeability, with low pressure loss and high flow rate;

3. Corrosion-resistant, high-temperature-resistant, and resistant to acids, alkalis, organic solvents, pharmaceuticals, etc., capable of long-term use in environments up to 480°C;

4. Easy to process, form, and weld;

5. Can be specially manufactured as reinforced, thickened, or with protective screens, as well as other specifications according to customer requirements.

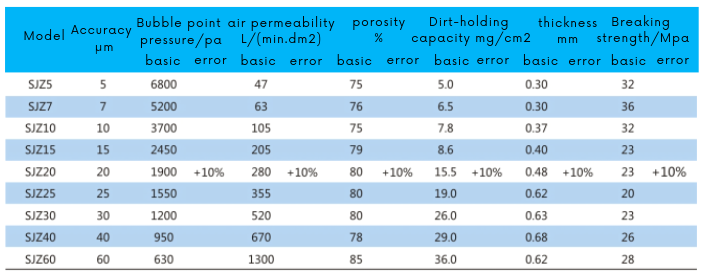

Technical parameters:

Main application

1.Polyester melt filtration in chemical fiber and membrane industries.

2.High temperature filtration and corrosion liquid filtration in petroleum industry.

3.Hydraulic fuel and lubrication oil filtration in mechanical equipment.

4.Liquid purification in pharmaceutical, biological and food & beverage industries.

How to choose between Sintered Metal Fiber Felt and sintered wire mesh

Choose sintered metal fiber felt for high dirt-holding capacity, flexibility, and applications requiring high surface area, such as catalysis or heat exchange, while sintered wire mesh is better for precise filtration due to its more uniform pore structure, and applications with higher impact resistance or where frequent, easier cleaning via backwashing is required. Consider the initial cost, cleaning cycle, filtration precision, and structural integrity needed for your specific application to make the right choice.

Choose Sintered Metal Fiber Felt When:

High dirt-holding capacity is critical:

The fibrous structure of felt allows it to hold more contaminants before needing cleaning or replacement, as W.S. Tyler explains.

Flexibility and formability are needed:

Metal fiber felt can be easily formed into complex shapes, making it suitable for a wider range of applications where mesh might be too rigid.

High porosity and lower pressure drop are desired:

Its high porosity leads to better flow and lower energy consumption.

High surface area is beneficial:

This is particularly useful for catalytic applications, heat exchangers, and mass transfer processes.

Choose Sintered Wire Mesh When:

Precision filtration is paramount:

The more structured and uniform pores of sintered wire mesh provide greater filtration accuracy than felt.

Structural integrity and strength are essential:

The laminated mesh offers excellent strength and durability, particularly for high-pressure applications.

Easy cleaning by backwashing is important:

Sintered mesh can be effectively cleaned using methods like backwashing, which is often more efficient than cleaning felt, which can trap particles.

Minimal blind porosity is a requirement:

Unlike felt, sintered mesh has minimal to no blind holes, ensuring better flow and less particle entrapment.

Considerations for Both:

Filtration Precision:

Mesh offers more accurate pore sizes than fiber felt, which can have inconsistent openings.

Cleaning and Maintenance:

Sintered felt requires longer cleaning cycles due to its higher dirt-holding capacity, while mesh is generally easier to backwash clean.

Cost:

Felt filters typically have a higher initial cost but offer long-term value through durability and performance, whereas mesh provides a more economical upfront investment.

Operating Temperature:

Both can handle a large range of temperatures, but felt may not be recommended for extremely hot applications due to potential particle reactivity with sintered bonds, according to W.S. Tyler.