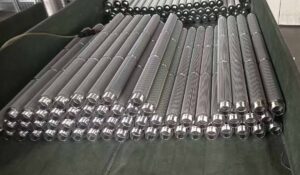

Pleated Metal Filter Elements

Product Introduction

The pleated metal filter elements is designed for demanding industrial applications requiring high precision, durability, and reusability. The primary filter media include stainless steel woven mesh and sintered fiber felt. It is used for melt filtration, like polymer melt, glass melt, etc. when the filter is used to filter polymer melt, the name is usually Polymer melt filters.

Woven mesh pleated filters provide smooth channels, easy cleaning, resistance to high temperature and corrosion, no fiber shedding, and extended service life.

Sintered metal fiber felt pleated filters feature a 3D porous depth structure with high porosity, excellent permeability, superior contaminant-holding capacity, and strong regeneration ability.

By combining a pleated design with robust materials, these filters deliver a 5–10× larger filtration area than regular cylindrical filters, ensuring longer cycles, lower pressure drop, and higher efficiency. Our pleated metal filter element can replace Mott’s Industrial Filter Cartridges in actual use with same specification and performance.

Key Features

Large filtration area – 5–10 times greater than standard cylindrical filters

Wide filtration precision range – 1–300 μm

High mechanical strength – withstands pressures up to 30 MPa

Temperature resistant – stable operation at up to 300°C

Reusable & easy to clean – strong regeneration and long service life

Flexible connection options – 222, 220, 226, threaded, flange, tie-rod, quick-connect, and custom designs available

Technical Specifications

Filtration Precision: 1–300 μm

Working Pressure: up to 30 MPa

Operating Temperature: up to 300°C

Dirt-Holding Capacity: 16.9–41 mg/cm²

Connection Types: 222, 220, 226, threaded, flange, quick-connect, tie-rod, custom options

Applications

Pleated metal filter elements are widely used across industries for liquid, gas, and polymer filtration:

Polymer Melt Filtration: Polyester, filament, staple fiber, and film production

High-Temperature Gas & Steam Filtration

Viscous Liquid Filtration: Chemicals, oils, and industrial fluids

These filters are ideal where durability, high strength, and precision filtration are critical.

Please check our product portfolio for more metal filters.