Standard Six-Layer Sintered Mesh Laminate

Product Introduction:

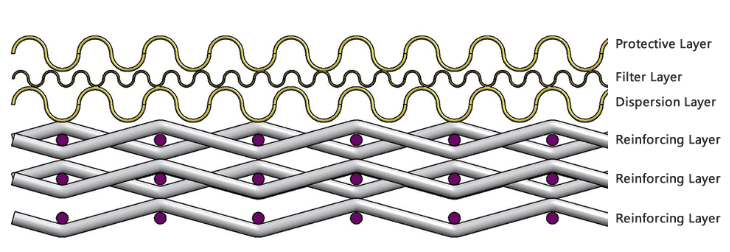

Six-Layer Sintered Mesh laminate is a new type of high-strength, structurally rigid filtration material made from six layers of stainless steel wire mesh stacked in a special configuration and vacuum sintered. The material is produced by adding one additional 8-mesh or 12-mesh square woven wire to the standard five-layer sintered mesh to enhance strength and diversion performance. The mesh openings of each layer are staggered to form a uniform and ideal filtration structure.

This material provides high filtration accuracy, low flow resistance, excellent mechanical strength, wear resistance, heat resistance, and cold resistance, as well as outstanding processability. Six-Layer Sintered Mesh is especially suitable for applications with high requirements for compression strength and uniform filtration accuracy, and is widely used in the food and pharmaceutical industries—particularly in two-in-one and three-in-one pharmaceutical equipment.

Product Features:

1. Cleanability: Excellent backwash performance due to surface filtration structure.

2. High strength: Excellent mechanical and compressive strength.

3. High precision: Uniform surface filtration performance for 1–300 μm.

4. Heat resistance: Can operate continuously from -200°C to 600°C.

Technical specifications

Standard materials: SUS304, SUS316L

Standard sizes:

1000mm × 500mm

1000mm × 600mm

1000mm × 1000mm

1200mm × 1000mm

1200mm × 1200mm

Filtration precision: 1–300 μm

Custom materials:

Monel alloy, 904L, etc., available upon request.

Six-Layer Sintered Mesh Structure