Product Overview

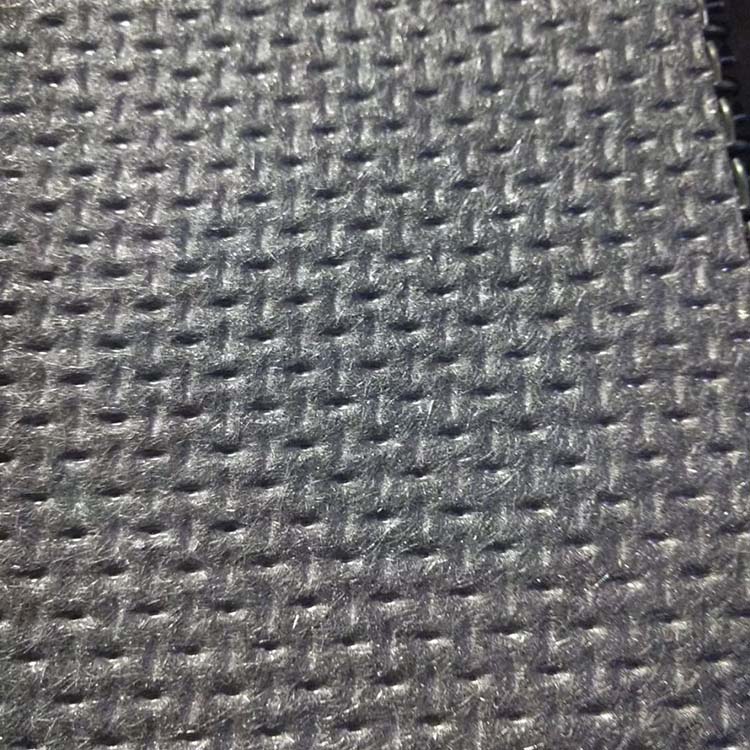

FeCrAl Sintered Fiber Felt is a high-performance metal fiber felt made by sintering iron-chromium-aluminum (FeCrAl) fibers at high temperatures. It is engineered to withstand extreme working conditions and provides outstanding performance in demanding industrial environments.

This advanced filter material offers exceptional benefits including long service life, high-temperature resistance, corrosion resistance, oxidation resistance, and carbon deposition resistance. With its uniform pore size distribution, high porosity, and strong contaminant holding capacity, FeCrAl sintered fiber felt delivers reliable filtration, thermal efficiency, and mechanical durability.

Specifications and Dimensions

Standard Material: 00Cr20Al6 FeCrAl Fiber

Standard Supply Size: 1180 × 1500 mm

Custom Options: Special sizes and specifications available upon request

Key Features and Advantages

High-Temperature Resistance: Stable operation up to 1200°C

Excellent Thermal Shock Resistance

Non-Water Absorbing & Minimal Thermal Inertia

Supports Radiant Combustion with high energy efficiency

Durable and Long Service Life compared to conventional filter media

Good Toughness and Foldability, making it easy to process into various shapes

Application Industries

FeCrAl sintered fiber felt is widely used in industries that require extreme temperature resistance, durability, and high-performance filtration:

Automotive exhaust treatment systems

Industrial burners and boiler retrofitting

Gas air conditioning systems

Glass annealing and high-temperature furnaces

Food baking, ovens, and heaters

Coated paper and drying processes

Parking heaters and coking plants

Industrial dust removal systems

Its incomparable performance advantages make it an ideal choice for next-generation energy-saving and environmental protection technologies.