Product Introduction

Powder Sintered Filter Elements are microporous metal filtration materials, manufactured from irregular stainless steel powders through cold isostatic pressing, mold pressing, or extrusion. As a result, they offer excellent permeability and filtration precision. Moreover, they provide high strength and toughness while operating at temperatures up to 300℃. Therefore, they are widely used in petroleum, chemical, and environmental industries as filtration materials, porous electrodes, sound-absorbing components, shock absorbers, cooling materials, catalyst carriers, and anti-freezing components. Our filter are equivalent to Mott Corporation porous metal filter elements.

Materials and Forms

Materials Available: SUS304, 304L, 316, 316L.

Forms: Tubes, plates, discs, rings, rods, and cones.

In addition, these options give customers flexibility to choose the most suitable form for their application.

Technical Specifications

Filtration Accuracy: 0.5–70 microns

Porosity: 30–45%

Permeability: 3–1300 M³/M²h·KPa

Working Pressure: 3.0 MPa

Operating Temperature: 600°C

Specific Surface Area: 10–40 cm²/cm³

Consequently, these filters can maintain stable performance in extreme conditions.

Performance Features

High Temperature Resistance – Normal operation below 500°C.

Mechanical Strength – Strong and machinable.

Corrosion Resistance – Effective in acids, hydrogen, and nitrogen.

Excellent Processability – One-time molding according to drawings.

High Filtration Precision – Superior purification effectiveness.

Uniform Porosity – Stable internal structure with no shedding.

Easy Maintenance – Excellent permeability, backflushing capability, and online regeneration.

Durability – Wear-resistant and impact-resistant.

Thus, customers benefit from long service life and reduced maintenance costs.

Product Applications

Because of their unique properties, sintered stainless Powder Sintered Filter Elements are applied across multiple industries:

Impurity removal and fine filtration in chemicals.

Pre-filtration for ultrafiltration, RO, and EDI systems.

Clarification filtration in food and beverage.

Recovery of precious metal catalysts in petrochemicals.

Precision filtration in pharmaceutical and chemical industries.

Oilfield reinjection water pre-filtration.

Steam and compressed air purification.

Flow restriction in pneumatic, lubricant, and hydraulic systems.

High-temperature decarbonization in dye production.

In short, these filters are versatile, efficient, and cost-effective for a wide range of industrial needs.

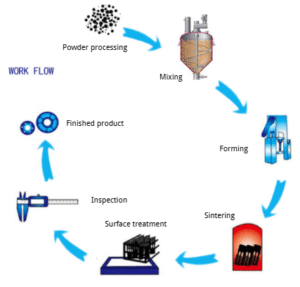

Production work flow:

To learn more metal filters, please check below.