Polymer melt filtration is one of the most critical steps in plastics, chemical fiber, film, and resin processing. Even tiny contaminants—such as gels, unmelted particles, carbonized residues, or metal fines—can quickly cause defects like black spots, broken filament, filter pressure spikes, and unstable extrusion. This is exactly why a polymer melt filter cartridges matters: it protects your extruder and improves product quality, while keeping the production line stable and efficient.

In real factories, polymer melt filter cartridges are mainly used in two mainstream forms: Pleated melt filter cartridge (folded structure) and Cylindrical melt filter cartridge (traditional straight tube). Both can be produced with stainless steel woven mesh or sintered stainless fiber felt. But the best choice depends on your working conditions—especially contamination load, melt viscosity, pressure limits, and cleaning method.

1) What Is a Polymer Melt Filter Cartridges?

A polymer melt filter cartridge is designed to remove impurities from high-temperature, high-viscosity polymer melt before it reaches spinnerets, dies, or critical downstream components. Unlike ordinary liquid filtration, melt filtration operates under very high pressure, high temperature, and high contamination sensitivity. Once the filter is wrong, it can lead to unstable pressure, frequent shutdowns, and high scrap rate.

Most polymer melt filter cartridges are made with two types of filter media:

Stainless steel woven mesh is made by weaving stainless wires together. It offers smooth flow paths, stable pore structure, high strength, corrosion resistance, and excellent cleanability. For processes where cleaning and reuse are important, woven mesh cartridges are a very common and economical choice.

Sintered stainless fiber felt is made by sintering micron-level stainless fibers under high temperature. It forms a 3D porous structure with high porosity and strong dirt-holding capacity. It is especially suitable for fine filtration and gel capture in demanding melt processes because it can trap contaminants in depth, not only on the surface.

2) Filter Media Structure:

In most polymer melt filtration systems, the filtration direction is typically from outside to inside. That means the polymer melt first contacts the outer layer, flows through the filtration layer, and then exits through the inner side.

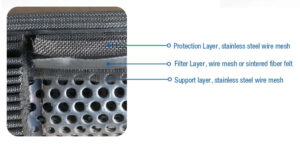

A typical melt filter cartridge media structure usually includes three layers (from outside to inside, following melt flow direction):

Protection Layer (Outer Layer)

The protection layer material is usually this layer can be stainless steel wire mesh, it is designed to shield the filtration layer from damage and prevent direct impact from large impurities. In real melt conditions, impurities can be sharp or hard (carbon particles, metal fines), and the protection layer helps avoid tearing, deformation, or premature failure. It also helps distribute the flow more evenly.

Filtration Layer (Middle Layer)

This is the “core” of the filter element. It performs the main separation job. this layer can be stainless steel wire mesh or sintered fiber felt. The pore size here defines the filtration rating (micron rating). Smaller pore sizes mean cleaner melt, but also faster pressure rise—so filtration rating must match your process carefully.

Support Layer (Inner Layer)

The support layer media is stainless steel wire mesh which ensures the filtration layer stays stable under high melt pressure. It prevents collapse or deformation and ensures consistent performance throughout the service cycle. Without strong support, the filter media can compress and reduce flow capacity dramatically.

These three layers can be manufactured in both cylindrical and pleated structures, which means you can apply the same filtration principle but get different performance in service life and pressure behavior.

3) Pleated vs Cylindrical: What’s the Real Difference?

Even when made from similar materials, pleated and cylindrical structures behave very differently in real production. Understanding their strengths helps you avoid frequent clogging and unexpected shutdowns.

Pleated Melt Filter Cartridges (Folded Type)

Pleated cartridges greatly increase effective filtration area by folding the media. In most melt filtration lines, this design provides better flow distribution and slower pressure rise.

In practice, pleated cartridges are preferred when:

- You want larger filtration area

- You need lower pressure drop

- You aim for longer service time

- Your process has moderate contamination load but continuous operation

Cylindrical Melt Filter Cartridges (Tube Type)

Cylindrical cartridges use straight media without folds. Their advantage is strong structural stability and simpler cleaning.

In practice, cylindrical cartridges are preferred when:

- Your system has high contamination load

- You plan frequent cleaning and reuse

- You need high compression resistance

- Your plant prefers a simpler structure for maintenance

4) Which One Should You Choose?

Many buyers think pleated cartridges are “always better,” but this is not always true. The best choice depends on your system reality. Here are practical factory-style cases to guide your selection.

Case 1: PET Fiber / Filament Line – Prefer Pleated

A PET filament plant struggles with frequent pressure spikes and short filter life on a spinning line. After switching from cylindrical mesh cartridges to pleated structure, the pressure increase becomes slower and more stable, allowing longer production cycles.

Why pleated worked: PET lines require stable melt flow. Pleated structure gives larger area, reduces pressure drop, and delays clogging.

Tip: For fiber/filament lines, choose pleated cartridges when you care about uptime and smooth pressure behavior.

Case 2: Recycled Plastic Melt – Prefer Cylindrical (or Pleated with stronger protection)

A recycled PP/PE plant has heavy contamination: carbon residue, dust, degraded gels. Pleated cartridges clog quickly within hours and folds may trap dirt unevenly. Switching to cylindrical cartridges improves stability and makes cleaning easier.

Why cylindrical worked: high dirt load makes pleated folds block quickly; cylindrical is more tolerant, stable, and easier to regenerate.

Tip: For recycled or dirty melt, cylindrical is often safer unless you design a stronger protection layer and staged filtration.

Case 3: Film Extrusion with Fine Defect Control – Prefer Fiber Felt (Pleated or Cylindrical)

A film line needs to eliminate gel points for high-end packaging film. Stainless woven mesh alone cannot fully control micro gels. Switching to sintered stainless fiber felt media significantly reduces gel defects.

Why felt worked: 3D depth structure captures gel-like impurities better than woven mesh.

Tip: If gel defects are your main problem, focus on media type (fiber felt), not only cartridge shape.

5) Main Applications of Polymer Melt Filter Cartridges

Polymer melt filter cartridges are widely used in:

- Polyester melt filtration in fiber and filament production

- Plastic granule extrusion and pelletizing

- Film, sheet, and cable production lines

- Resin and adhesive melt filtration

- High-temperature viscous polymer processing (engineering plastics, specialty resins)

Wherever melt purity affects your final product appearance and mechanical quality, melt filtration becomes a key control point.

6) Connection Options for Polymer Melt Filter Cartridges

To fit various filter housings and line designs, melt filter cartridges can be supplied with:

- Standard connections (222, 220, 226)

- Quick interface

- Thread connection

- Flange connection

- Tie-rod structure

- Special customized connections

Correct connection choice reduces bypass leakage and ensures stable filtration performance under high pressure.

About FiltraMate

At FiltraMate, we manufacture and supply polymer melt filter cartridges in both pleated and cylindrical types, using stainless steel woven mesh and sintered stainless fiber felt media. Based on your polymer type, melt viscosity, contamination load, and filtration target, our engineering team can help you select the right structure, micron rating, and connection style—so your line runs longer, cleaner, and more stable.