Dairy industry filtration plays a critical role in ensuring product quality, food safety, and stable operation of production equipment.

From raw milk reception to final packaging, many different fluids and gases come into contact with the product or processing environment. If these media contain particles, oil, moisture, or microorganisms, they can directly affect taste, shelf life, and hygiene standards.

This article introduces the most important filtration points in dairy production, explains why filtration is needed at each stage, and discusses typical filter solutions used in the industry.

1. Filtration at Raw Milk Reception & Pre-Treatment

Raw milk arriving at the plant may contain impurities such as hair, feed particles, sand, and coagulated proteins. If these contaminants enter downstream equipment, they can cause wear, blockages, and hygiene risks.

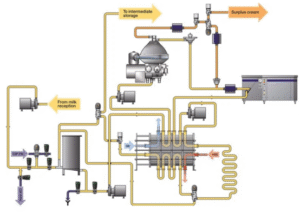

During milk reception and initial transfer, pre-filtration is usually installed before storage tanks and separators. The main purpose is to remove coarse particles and protect pumps, valves, and heat exchangers.

Commonly used filter types include stainless steel mesh filter cartridges or pleated liquid filter cartridges with micron ratings typically between 50–200 μm.

Typical scenario:

Milk is unloaded from tanker trucks and passes through a pipeline strainer or cartridge filter before entering the raw milk silo. The filter captures visible particles, preventing them from circulating through the process.

2. Process Water & Ingredient Water Filtration

Water is one of the most important “ingredients” in dairy production. It is used for:

• Product formulation

• Equipment rinsing

• Cooling and heating systems

• CIP cleaning

If water contains sediment, rust, microorganisms, or organic matter, it can directly affect product quality.

Typical filtration systems include:

• Multimedia or sand pre-filters

• Cartridge filters (5 μm, 1 μm, or finer)

• In some plants, membrane filtration (RO, UF)

Typical scenario:

Municipal water is filtered through a 5 μm PP cartridge before being used for dissolving milk powder or sugar. This prevents fine particles from entering the mixing tank and ensures consistent product texture.

3. Compressed Air & Sterile Gas Filtration

Compressed air is widely used in dairy plants for:

• Valve actuation

• Product transfer

• Tank venting

• Packaging machines

• Aseptic filling zones

However, compressed air naturally contains oil aerosols, moisture, and particles. Without proper filtration, these contaminants may enter contact areas and cause microbial growth or product contamination.

Typical air treatment systems include:

• Particulate filters

• Coalescing filters

• Sterile air filters

Typical scenario:

Compressed air feeding an aseptic filler passes through a coalescing filter to remove oil and water aerosols, followed by a sterile-grade filter to remove bacteria before entering the filling chamber.

4. Other Important Filtration Points in Dairy Processing

Besides the three major areas above, filtration is also applied in several supporting process steps:

Product Filtration Before Heat Treatment or Filling

Fine cartridge filters are sometimes used to remove agglomerates or undissolved solids, ensuring smooth flow through heat exchangers and fillers.

CIP System Filtration

Cleaning solutions circulate through filters to prevent removed debris from re-entering pipelines and spray balls.

Equipment Protection Filters

Hydraulic systems, lubrication systems, and vacuum pumps use filters to protect moving components.

5. What Filter Elements Must Meet in Dairy Applications

Filter elements used in dairy plants should offer:

• Food-grade compliant materials

• Stable filtration efficiency

• Low pressure drop

• Easy cleaning or replacement

• Resistance to cleaning chemicals and temperature

Stainless steel filters, PP cartridges, and high-quality pleated cartridges are commonly selected depending on the application.

6. FiltraMate Solutions for Dairy Industry Filtration

At FiltraMate, we supply a wide range of industrial filter elements suitable for dairy processing, including liquid filter cartridges, stainless steel filter elements, coalescing filters, and compressed air filters.

Our products are designed to deliver reliable performance, consistent quality, and long service life, helping dairy producers maintain stable operation and high product standards.

If you are looking for filtration solutions for your dairy plant, FiltraMate is ready to support your project.